In the ongoing fight against environmental hazards, especially those posed by oil spills and industrial fires, it is essential to develop effective and robust containment systems paramount. Among these systems is Fireboom.

Fireboom is a solution to combat the spread of fires on water, with great heat resistance and fast processing speed.

Designed with emphasis on precision and durability, flexibility in transportation, deployment, and ease of repair and maintenance.

Complementing the Fireboom is the High Temperature Boom Repair System, which provides fast and effective solutions to maintain the integrity of containment barriers.

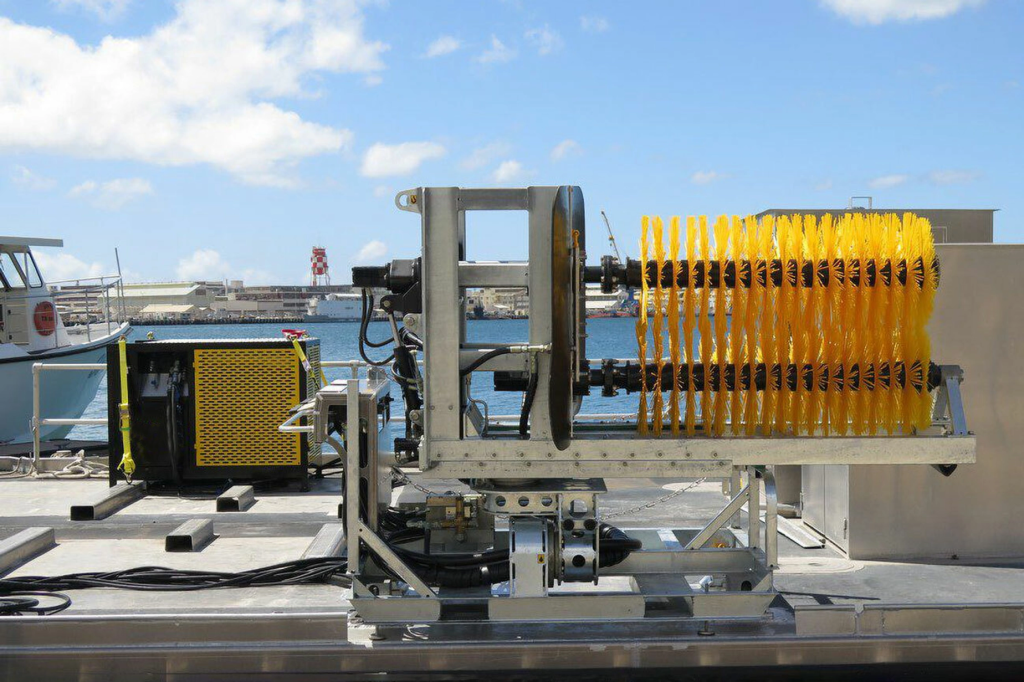

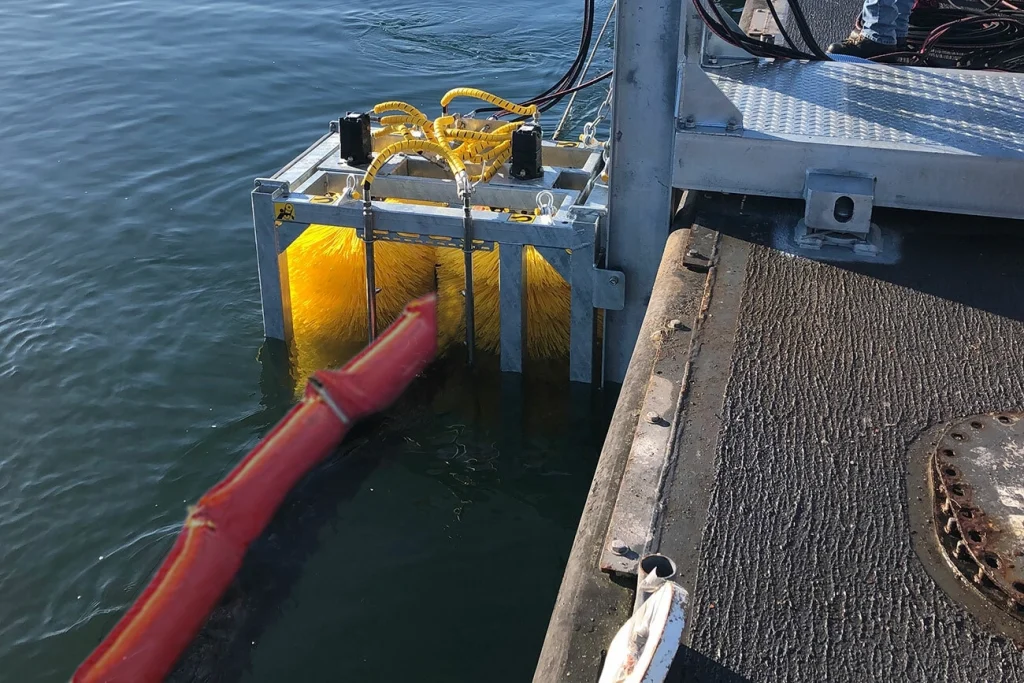

Further enhancing the effectiveness of containment operations is the Boom Cleaning System, designed to remove pollutants and contaminants from floating surfaces.

System components:

-Fireboom

-01 set High temperature boom patch repair system

-01 set boom cleaning system

When working together, these systems represent a comprehensive approach to responding to oil sprill emergencies and protecting the environment in a cost-effective and long-term manner.

| FIRE BOOM TECHNICAL DATA | |

| Heat Resistance | -343°C to 1,260°C |

| Oil removal efficiency | 95% |

| Disposal Rate | 10,000 l/ hour |

| Control burn | 11 hours |

| High temperature resistant ceramic core flotation surrounded by two layers of stainless steel knitted mesh and high temperature resistant texible fabric that can withstands temperature of 1,260 °C continuous | |

| Density of Ceramic Foam | 32 – 40 kg/m |

| The segments of the boom are encased in tubular PVC outer cover that is extended to form the skirt and connected by galvanized chain ballast | |

| A stainless steel internal tension cable runs the length of the boom section | |

| Total length | 150 m |

| Total height | 760 mm |

| Float | 300 mm |

| Skirt | 450 mm |

| Section length | 15 m |

| Weight | 12 kg/m |

| Ratio between Buoyancy and Weight | 3.8:1 |

| 5 Layer Structure: Cover Layer is PVC, 2nd Layer is Stainless Steel Knitted Mesh, 3rd Layer is High Temperature Resistant Ceramic Textile, 4th Layer is Stainless Steel Knitted Mesh, Core Layer is High Temperature Resistant Flotation Core | |

| Buoy pull system | 2 pull ropes, each 120m length |

| Storage | 20 FT Container |

| Suspension system: capable of moving, with a sliding hook system on the roof of a 20FT container | |

1. FIREBOOM

Fireboom is used to prevent the spread of fires on water, with heat resistance ranging from -343°C to 1,260°C, along with an oil removal efficiency of 95%, processing speed of more than 10,000 liters per hour.

Engineered for precision and durability and flexibility, the Fireboom includes interlocking stainless steel connectors that facilitate seamless assembly and disassembly during deployment. Its innovative design incorporates a high-temperature-resistant embossed ceramic core, surrounded by layers of stainless steel knitted mesh and heat-resistant textile, ensuring resilience in harsh conditions. Additionally, the Fireboom’s configuration includes a tubular PVC outer shell that is expanded to form a protective shell, reinforced with galvanized chain ballast to ensure stability.

II. High temperature BOOM patch repair system

Restech offers kits to repair compartment booms using hot air gun technology for Thermoplastic fabrics or glue for booms.

The components:

Hot air gun with nozzle (110 or 220V) : 01 unit

Silicon roller: 01 unit

Fabric : 01 set (PVC, PU or XR5)

Tool box: 01 set

III. FLOAT CLEANING SYSTEM

The boom cleaning system also incorporates sturdy structural elements, including a powder-coated steel frame with lifting hook, tires and axle, ensuring portability and stability during deployment.

| Float cleaning system | |

| Pump flow | 15 l/min |

| System Dimension (L x W x H) | 991 x 787 x 1,245 mm |

| Volume | 30 l |

| Maximum pressure | 3,200 psi |

| Hot water generating system | Beckett burner type that operates on Diesel fuel |

| Engine | 4 stroke diesel engine, air cooled |

| Power | 9.8 HP |

| Capacity | 442 cc |

| Bore x stroke | 86 x 76 mm |

| Torque | 18 Nm |

| Compression ratio | 20.3:1 |

| Weight | 45 kg |

| Lubricating oil volume | 1.5 l |

| Engine emission standards | Tier 4 |